The Crucial Practices of Proof load testing and servicing

- Freddie Tay

- Oct 21, 2023

- 2 min read

Ensuring Safety and Reliability

The testing and servicing of equipment play a pivotal role in guaranteeing the safety and reliability of machinery dedicated to hoisting and transporting heavy loads. This meticulous process involves a comprehensive series of inspections, maintenance tasks, and performance assessments, all aimed at ensuring that lifting equipment operates at its peak capacity while adhering to rigorous safety standards.

Visual Inspections: The First Line of Defense

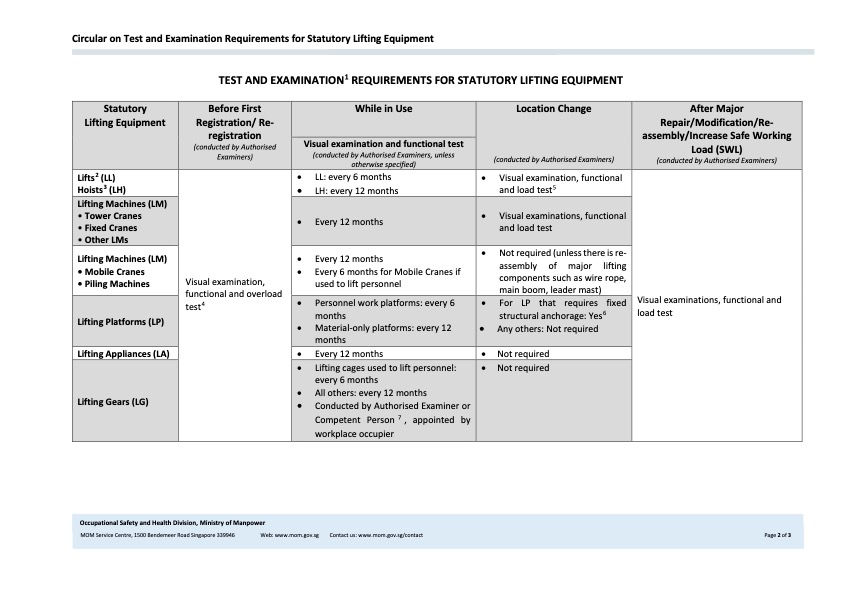

Inspections stand as the cornerstone of this process. Regular visual examinations, often conducted daily or before each use, are indispensable to spot any visible signs of wear, damage, or malfunction. These routine checks serve as the first line of defense against potential hazards. More in-depth inspections, typically carried out on a quarterly or annual basis, involve a thorough assessment of the equipment's structural integrity, functionality, and compliance with regulatory guidelines.

Load Testing: Simulating Real-Life Scenarios

A critical component of the process is proof load testing, where loads that simulate real-life scenarios are applied to assess the equipment's capacity and safety. This crucial step is typically performed after the installation of new equipment and during periodic re-certifications like MOM testing.

Servicing: Beyond Maintenance

Servicing extends beyond mere maintenance; it is a comprehensive approach often conducted by trained technicians with expertise in the specific type of lifting equipment. Tasks may include re-certification, load cell calibration, and the replacement of lifting equipment, ensuring that the rigging equipment complies with current safety standards.

Commitment to Safety and Operational Efficiency

In essence, the testing and servicing of lifting equipment are not merely matters of compliance but a profound commitment to safety and operational efficiency. By meticulously following these practices, organizations can safeguard the well-being of their personnel and the integrity of their operations while upholding stringent regulatory requirements.

Investing time and resources in these practices is an investment in the longevity of equipment, the safety of workers, and the overall efficiency of operations. As lifting equipment remains a critical component in various industries, prioritizing these practices is

an imperative step towards a secure and reliable workplace. #TestingandServicing #Singaporetesting #Momtesting

Comments